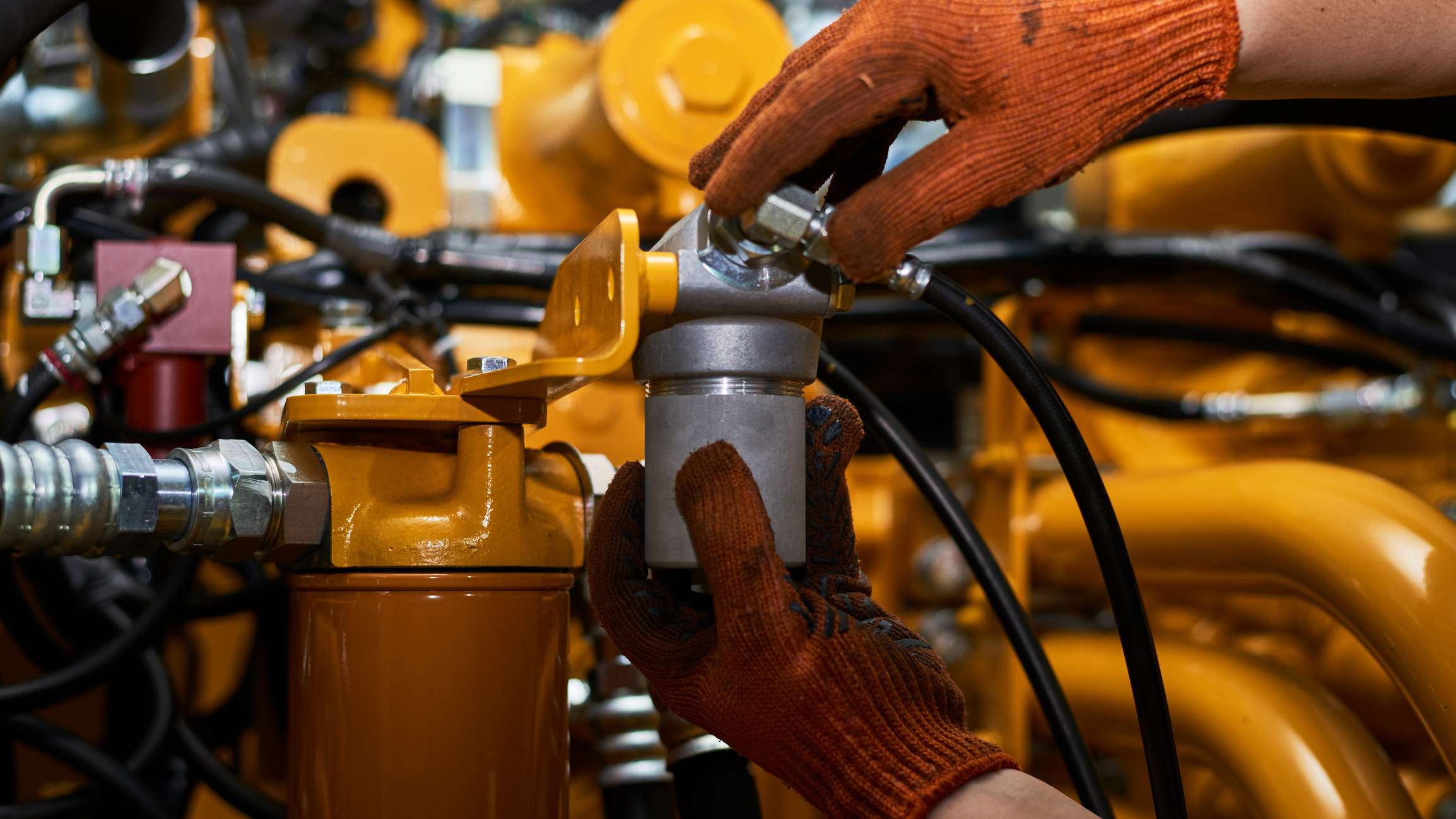

Due to the complexity of a hydraulic system, diagnosing problems can be difficult. Some problems can go unnoticed for several months until they are so severe that your system breaks down. If neglected, hydraulic problems can cost your company money in major repairs and disruption in your productivity. So, if you need hydraulic system repair, don’t hesitate to contact professional hydraulic repair services In Ardmore. A licensed technician can inspect your hydraulic system, diagnose the problem, and fix it right away so that your team can get back to work. Below, we look at four signs you may need to repair your hydraulic system.

1. Fluid Temperature Too High

One of the most common problems with hydraulics is overheating, which often occurs due to an inefficient system. The more inefficient the system is, the more it loses power, resulting in greater heat production. If the pump, valves, plumbing, and actuators all have to work hard, the hydraulic system will eventually overheat. So, that begs the question, how hot is too hot? You want to keep hydraulic fluid temperatures below 180°F. Once the fluid exceeds 180°F, it can damage the hydraulic seals. However, there’s something else to consider. Any hydraulic fluid is too hot when viscosity falls below optimum performance for the system. If you notice more friction between the moving parts, the fluid is too hot even if it doesn’t reach 180°F.2. Slow Operation

Speaking of hydraulic fluid, if you notice that your hydraulic system has slowed down, the decreased speed is caused by a loss of fluid flow at the point of use. Why is there a loss of flow? The answer is most likely an internal or external leak.External Hydraulic Fluid Leak

External fluid leaks are easy to spot because they are outside the hydraulic system. In most cases, you can find a leak around hoses or valves. The hose may be torn or have a loose connection.Internal Hydraulic Fluid Leak

Internal hydraulic fluid leaks are more difficult to diagnose because they occur deep within the hydraulic system. Most leaks occur at key operating points such as the actuator, valve, or pump. Since leaks can affect a hydraulic system’s efficiency and impact heat load, high fluid temperatures and slow operation are often related. Once a technician performs hydraulic system repair, you should notice lower fluid temperatures and a faster operation.3. Noisy Hydraulic System

By nature, a hydraulic system is a noisy system much in the same way as a vacuum cleaner, dishwasher, or blender. Only through careful engineering and design can a manufacturer achieve a noise-free system. As such, much of today’s hydraulic equipment is impressively quiet. So, if repetitive, odd, or loud noises are coming from the system, a problem is likely. When scheduling hydraulic repair services, one of the greatest challenges technicians face is locating the source of the noise. There are several possible culprits: the motor, pump, valves, fluid conductors, or actuators (or something else).- Hydraulic motor: worn-out bearings, rotor, or fan.

- Hydraulic pump: worn-out bearings, vanes, pistons, rotors, or gears

- Hydraulic valves: rapid drop in fluid pressure, loose or damaged seals

- Fluid conductors: plumbing pressure pulsations, loose tubing

- Actuators: air, fluid foam, or contamination in the hydraulic fluid