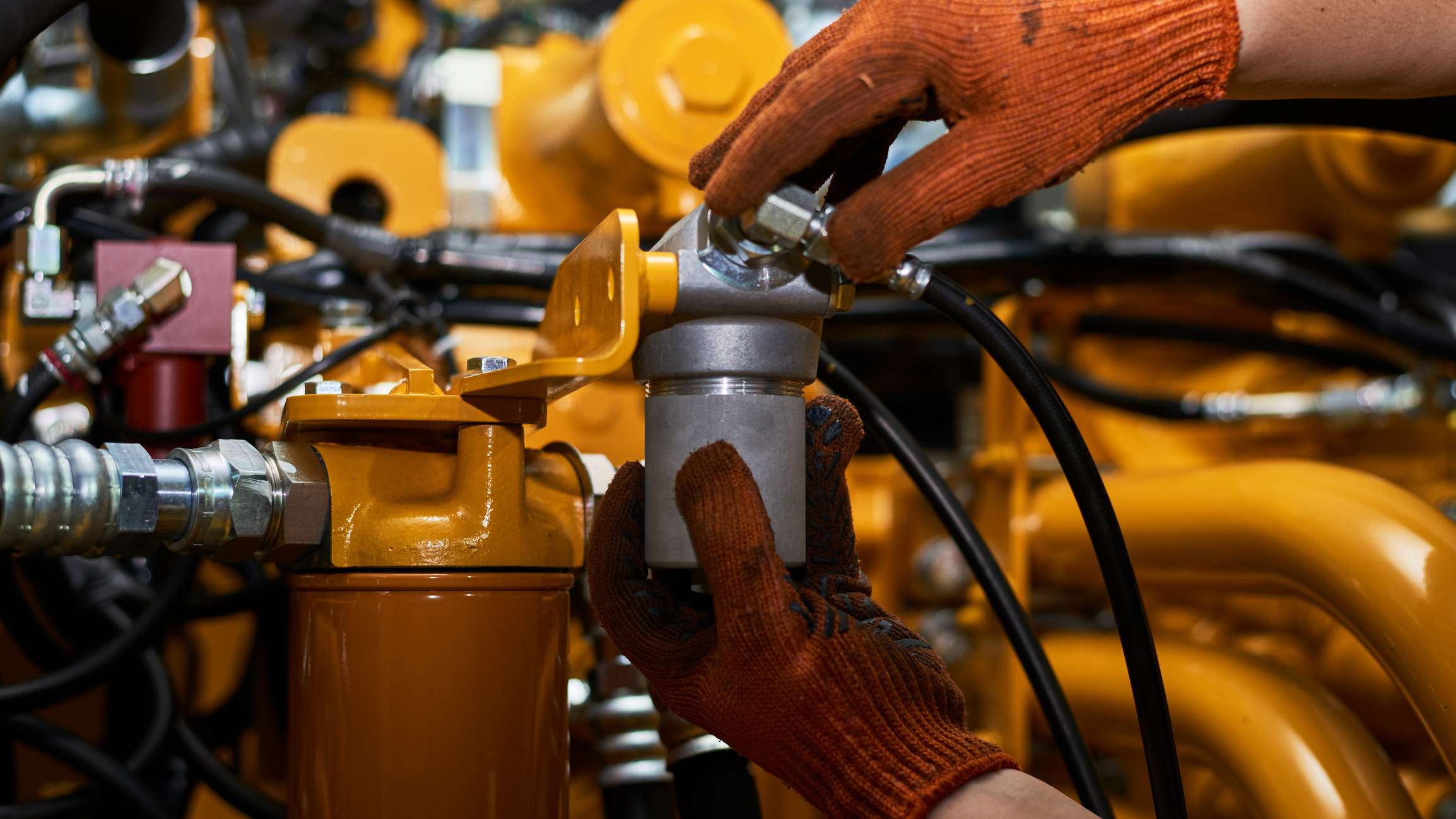

Hydraulic systems are the standard operating systems that you see in many service and utility trucks here in Ardmore, Oklahoma. The purpose of a hydraulic system is to run cranes, fluid pumps, and hydraulically-driven tools. So, what happens when you don’t take care of your hydraulics? If you fail to maintain or care for your equipment, you will need hydraulic repair or replacement. Learn more about the importance of proper care for your hydraulics.

The Importance of Caring for Your Hydraulic Equipment

Although there are several reasons you should take care of your hydraulics, there’s one that stands out above the rest. The safety of you, your employees, and even your customers may be on the line. A poorly-maintained hydraulic system is likely to break down, and this poses a significant safety threat. Unfortunately, workplace accidents are common and often attributed to broken equipment.

Consider the issue of a leaky hose. If you have a leak, it can create slip and fall hazards, fire danger, and skin burns. Under high pressure, the fluid can penetrate the skin. The most common causes of leaking hoses are abrasions and improper assembly. By caring for your equipment, you make the workplace safer.

If safety alone isn’t a reason for you to care for your equipment, there are a few other advantages to providing your hydraulics with rapid repairs and regular maintenance. All of the following are benefits of proper care and maintenance:

Spend Less Money

If you fail to perform normal upkeep and maintenance, your neglect can result in costly repairs. It is true that even a simple action such as changing the oil can be expensive, but maintenance is less expensive. In the end, your neglect will decrease the lifespan of your equipment and result in a need for frequent repairs.

In an effort to save money, you might want to skip out on routine maintenance or hold out to make a repair. But, the longer you wait to repair or maintain your equipment, the more expensive your repair bill will be.

Increased Productivity

Your business can greatly benefit from hydraulic hose repair in Ardmore. When you seek out quick repairs or receive routine maintenance, you keep your

equipment running at an optimal level. If your equipment breaks down due to a serious problem, you may have to shut down operations for several days.

Time is money, and downtime due to the failure of mistreated hydraulic equipment can spell out lower profit margins for businesses and owners. Faults can easily become malfunctions, and this might cause a halt in the overall productivity in your business. Why risk losing income when you can take measures to keep your equipment working well?

Breakdowns aside, your quality care can also increase your speed. When your equipment receives the right attention, it works well. You may notice a significant increase in productivity when you take care of your equipment. A hydraulic repair service helps you make more money.

Are You Caring for Your Equipment to Prevent the Need for Hydraulic Repair?

Now that you know the importance of proper care, you might be wondering how you can keep your hydraulics in prime condition. First and foremost, you should always work with a

hydraulic equipment repair company you can trust. They will be able to provide the maintenance and repairs that you need.

Here are a few other tips:

Be Organized

Create and maintain an up-to-date maintenance log so that all employees are abreast of the servicing schedule. Everyone should know what services were performed in the past.

Provide Training

Ensure that all employees who work with the hydraulic equipment have training in the use and maintenance of the equipment. Furthermore, their training should be equivalent to the level which their specific duties require of them.

Choose the Right Company

Not all companies offer the same level of care. Before you hire someone to work on your equipment, look into their reputation. Make sure they have the licensing, insurance, and services you need.

Frequently Asked Questions:

What are the four reasons behind the hydraulic hose failure?

There are four common reasons for hose failure. First, there’s water or particulate contamination. Hydraulic systems have filters to address particulate contamination. However, if those filters don’t receive proper maintenance, they don’t work well. Another cause of the failure is external damage. According to research, about

80% of hose failures are from external physical damage. This includes pulling, kinking, and crushing the hose.

One of the more common causes of failure is multi-plane bending. Even a small kink can reduce the life of your hydraulic hose by as much as 70%. Finally, aeration or cavitation could result in failure. Both of these dysfunctions can cause knocking, whining, and banging noises.

Why is the maintenance of your hydraulic hose important?

Maintenance of your hydraulic hoses is important in maintaining the proper functioning and preventing leaks. If you have hose damage, you may have hydraulic fluid all over your floor or damage from system contamination,

A leaky hose doesn’t just pose danger to the equipment. Sadly, the leak can become a hazard to staff working around the machine. Hydraulic fluid can lead to slips and falls, skin burns, irritation, and other liabilities. To reduce the risk of a leak, you can protect the hose cover with nylon and urethane Sleeving and spring guards. By working with the right company to pick your hoses, you can also reduce the likelihood of a leak.

How do you troubleshoot a hydraulic system?

If you want to troubleshoot your hydraulic system, you should expect to spend a few days diagnosing the issue. Unless you studied hydraulics, you don’t have the training or skills needed to troubleshoot a hydraulics system. Your best bet is to call a professional.

If you are in search of a top-of-the-line hydraulic repair service that specializes in hydraulic hose repair within Ardmore, Oklahoma,

contact Elliot Equipment Rentals. We are your first choice for a hydraulic equipment supplier, and we go to great lengths to tackle your hydraulic equipment repair.