Buying a hydraulic pump might seem like a simple task, but it’s not. There are many types and styles of pumps, which makes finding the perfect pump nearly impossible. Before you go in for hydraulic repair near my location, learn more about the types of pumps in Ardmore and how you can pick the right one for your needs.

All the Types of Hydraulic Pumps

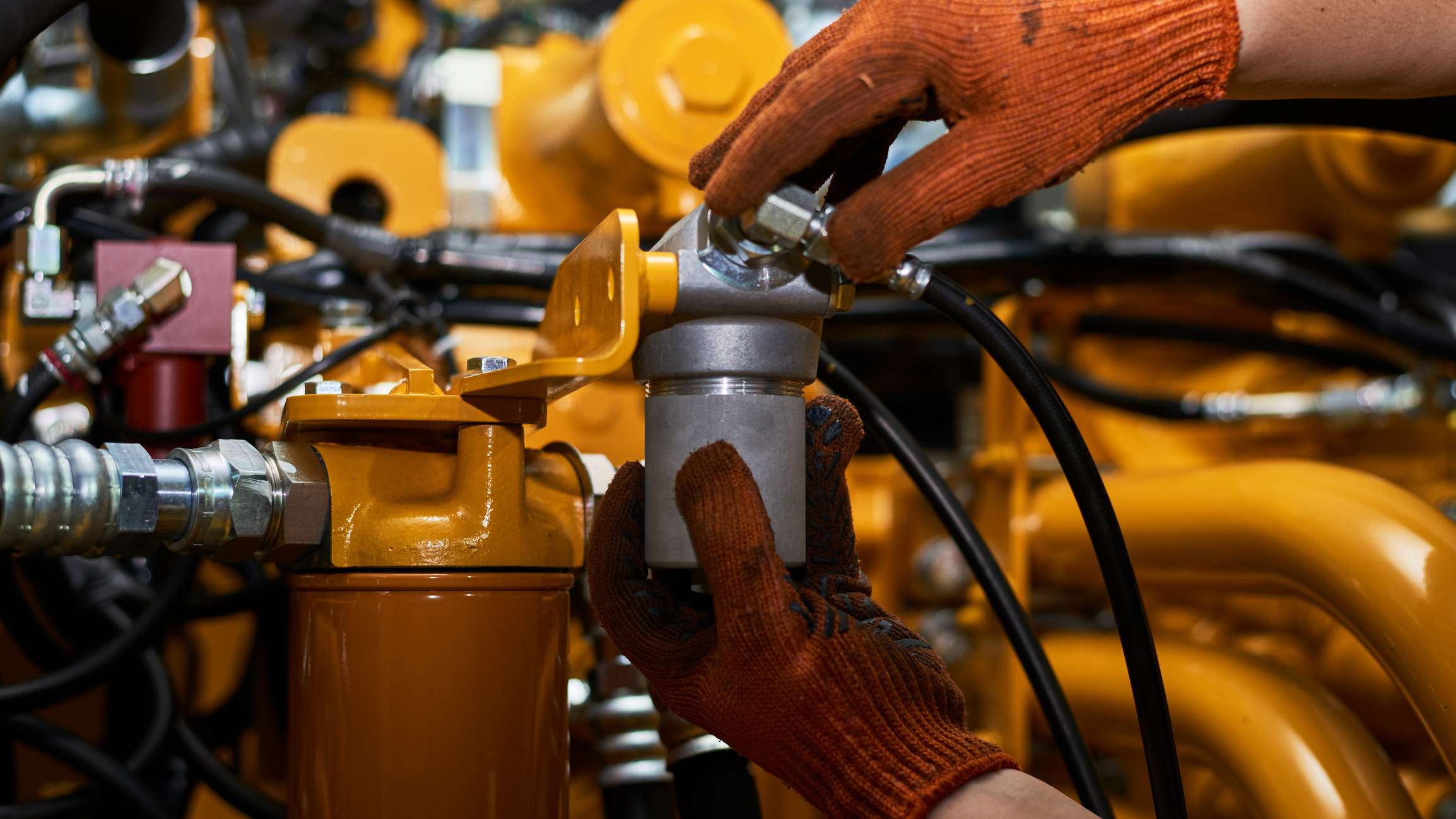

If you want to know more about the types of hydraulic pumps, you need to understand how they work. Hydraulic pumps use fluid displacement to transform mechanical energy into hydraulic form. For this to occur, a pump inlet makes a vacuum and uses the pressure to pull liquid out of the reservoir. The pump moves in whatever way it was designed to and then pushes the liquid out into the other parts of the hydraulic system.

Although pumps vary, they all use either positive or non-positive displacement to make energy. The energy affects the flow rate of the liquid. In a

positive-displacement or hydrostatic pump, the fluid gets trapped and displaced. The volume is always the same, and the pressure never increases. Typically, these pumps are ideal for low-pressure uses.

Meanwhile, a non-positive pump adjusts the speed of the fluid and makes a continuous flow. Because of this, the pressure of the system changes every cycle. The maximum pressure is always higher than the pressure created from a hydrostatic pump. Both centrifugal and propeller pumps are examples of this.

Types of Positive-Displacement Pumps

Most hydraulic pumps rely on positive displacement. Therefore, if you’re shopping around for a new pump, you can expect it to be one of the following:

- Gear pump

- Vane pump

- Piston pump

- Inline axial pump

- Radial-piston pump

- Bent-axis pumps

Things You Should Consider Before Buying

Before choosing a new hydraulic pump, you should think about your wants and needs. All of the following are factors you should consider before you buy a new pump. Of course, speaking with a hydraulic equipment repair service can help you make a choice.

Flow Rate

You can calculate the flow rate of a pump by looking at the pump speed revolutions per minute, the pump efficiency, and the displacement value. Generally, pumps have maximum flow ratings measured in either gallons per minute or liters per minute.

The flow rate tells you how much a pump can move and whether or not it is appropriate for your needs. If you don’t buy a pump that’s fast enough, you’ll have constant trouble.

The Fluid

While most hydraulic pumps use standard hydraulic fluid, there is some variation in the types of fluid. If you have a preference, make sure the pump you buy uses the fluid you want. For instance, some fluids are biodegradable. Others have high viscosity. When considering a pump, research the type of oil you need.

Power Curves and Torque Ratings

The power of a pump correlates with its torque and rotation speed. Before you buy a pump, you should know the torque needs of your machine. Meanwhile, the power curves give you a clear visual of how much power the pump requires at specific rates of flow.

Speed

Operating speeds vary by pump design. To quantify the operating speed, manufacturers measure the revolutions per minute of the driveshaft.

Maximum Operating Pressure

Most pumps list their maximum operating pressure in PSI or bars. As you look at this value, remember that the pump doesn’t make pressure. The pressure is a result of the load on the fluid.

The maximum operating pressure tells you how much pressure a pump can take without leaking or causing damage to the parts. Usually, there’s extreme variation between these values. It should be one of your first considerations when you pick a pump.

Fixed Displacement or Variable Displacement

At times, hydraulic pumps are available in either fixed displacement or variable displacement models. The major difference is in the amount of fluid displacement. If you have a fixed displacement model, you can easily do the same job over and over again. A variable pump has a variety of uses and works with more tools than the alternative model.

Maintenance

When it comes to your new hydraulic pump, you need to think about the maintenance. Certain pumps are more maintenance-sensitive than others. If you have a high-maintenance pump, you need to be willing to put in the time and money to take care of it.

As a general rule, variable displacement pumps cost more than other types. However, design adaptations can make specific models easier to maintain than others. For instance, a vane pump requires less attention than internal pumps. They extend out more if the casing shows signs of wear.

Although axial and bent-axis pumps are complex, they tend to do well when it comes to longevity. If you want to learn more about the maintenance needs of your new pump, speak with your hydraulic equipment repair service.

Your Preferences

While the details above are all mechanical, it’s worth considering your own preferences. Is there a manufacturer you like to work with, or one that your repair company recommends? If so, you may want to look into their offerings.

Additionally, you might have a desired noise level. In a small shop, a noisy hydraulic pump could cause problems. Be mindful of the noise when you choose a pump. Also, take into consideration the way in which you operate your pump and how it fits into your business.

Find a Hydraulic Repair Near My Location

If you’re starting to lose sleep over your hydraulic pump, it’s time to stop worrying. You don’t need to make the decision on your own. Let an experienced hydraulic repair company take on the task.

Here at Elliott Rental and Equipment, we have years of experience working on hydraulic equipment. We take the time to understand your needs and use our knowledge to pick the right pump for the job. When you have us by your side, you can trust your Ardmore hydraulic equipment is in good hands.

Stop looking for a hydraulic repair near me and

give us a call. We’re ready to help.